The IQ-OPTION is an inline vision sensor for the ITK module that detects mixing-copies, as well as printing and die-cutting defects on folding and corrugated cartons. Compared with conventional Pharmacode and Colorcode sensors, the IQ-OPTION is the world’s best-of-breed device.

The sensor performs the quality inspection either on carton-level (in Folding/Gluing machines) or on sheet-level (in Offset-, Rotogravure-, Flexographic-Printing machines). It employs advanced, patented machine-vision algorithms that use miniature, colored DATAMATRIX symbols to check for:

- Product and LOT Mixing (Mixing-Copy verification)

- Print-to-Cut Registration Displacement and/or Rotation

- Missing Colors

- Color Misregistration

- Color Fidelity Failure (i.e. Intensity, Saturation, Dot-Gain, and Tone-Value)

Unlike conventional devices, the IQ-OPTION sensors dynamically compensate for carton-white during color-intensity measurements and calculate separate intensity histograms for each individual color. They are the only devices to measure the registration of individual colors on a carton/item-level, so as to detect artwork fidelity failures on cartons that reside at the edges of large boards (i.e. 1000×1400 sqmm).

Moreover, thanks to SENSAP’s advanced machine-vibration compensation technology, the sensors are capable of measuring the Print-to-Cut registration, on a carton/item level, with unparalleled accuracy (i.e. >50 microns) at the highest machine-speed.

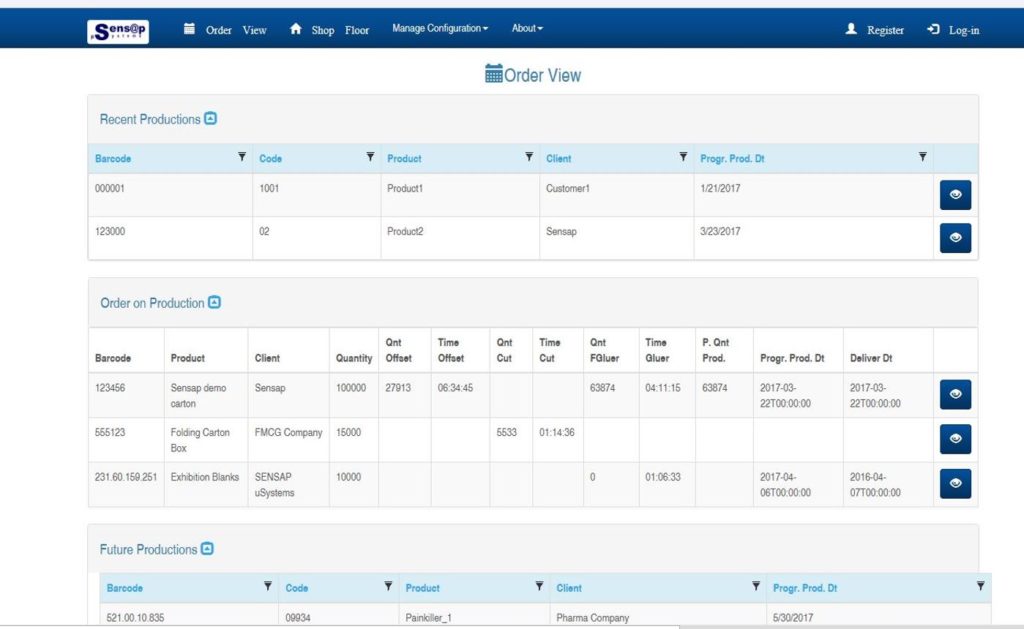

The sensors store actual images and individual defect descriptions of non-conforming items for each separate production run (LOT).

The IQ-OPTION sensors retrofit to almost any piece of printing and folding/gluing equipment and facilitate easy operation and automatic setup thanks to SENSAP’s advanced autoTEACH and autoSET technologies.

Product Highlights

► Item-Level and/or Sheet-Level Carton-Quality Inspection

► Automatic Compensation for Carton-White for precise Color-Intensity and -Registration measurement

► Separate Intensity Histograms derived for all Colors of each individual item (carton/sheet)

► Extreme Dimensional Measurement Precision thanks to SENSAP’s machine-vibration compensation technology

► Actual Images and Defect-Descriptions stored for each non-conforming item (carton/sheet)

► Miniature printed symbols used for quality check of miniature cartons

► Unparalleled performance: quality inspection at machine speed up to 600m/min or 50pcs/sec

► Easy mounting onto almost any piece of printing, die-cutting, folding, and gluing equipment

► Easy Operation & Automatic Setup thanks to SENSAP’s advanced autoTEACH™ and autoSET™ technologies

INTEGRA Q-OPTION

It detects manufacturing defects, in the Printing, Die-Cutting, and Folding/Gluing processes, ensuring that every single carton meets the highest quality standards. The sensor checks for:

- Missing Colors,

- Print-to-Cut Registration Displacement and/or Rotation,

- Product and LOT Mixing