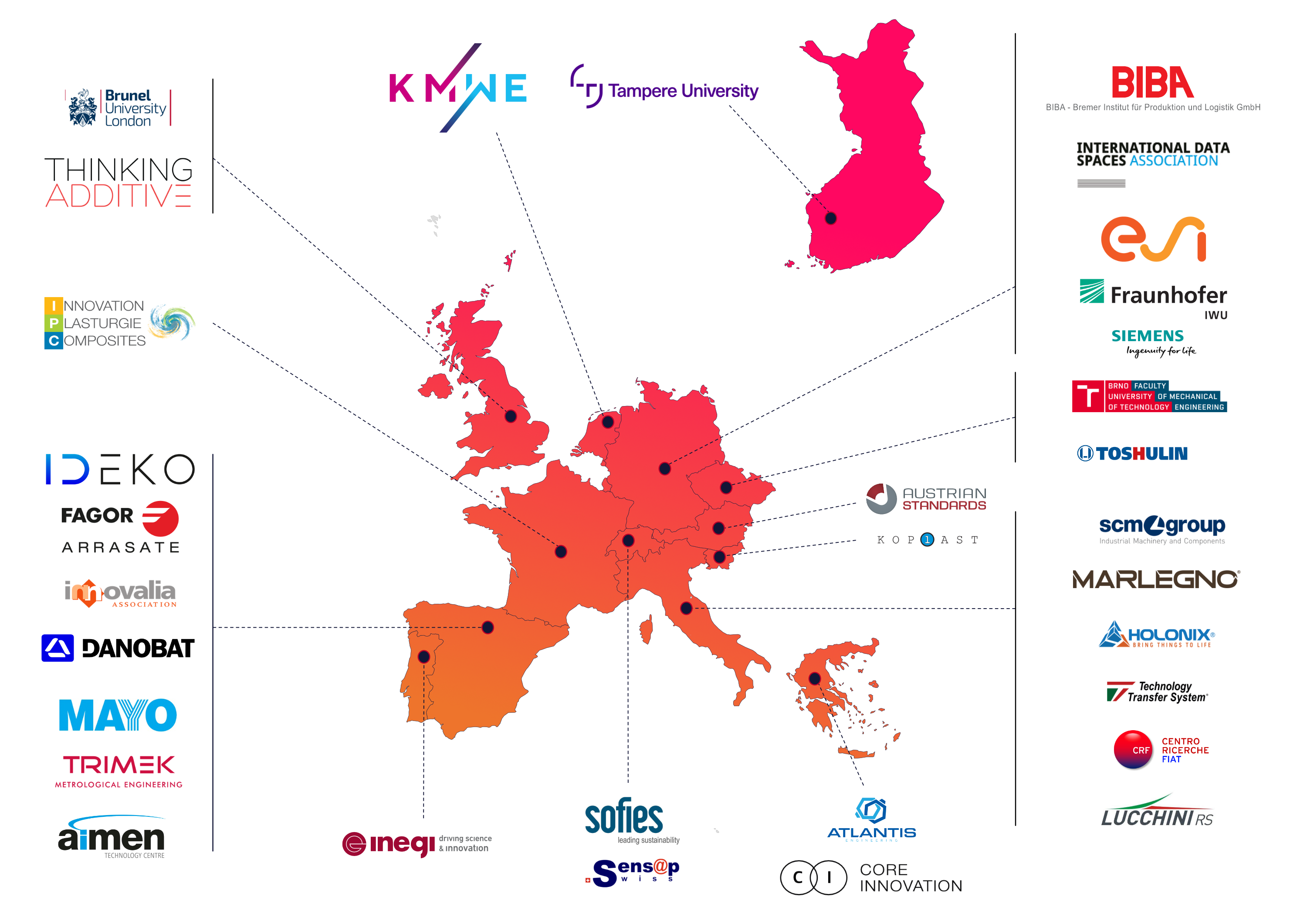

Protocols and Strategies for extending the useful Life of major capital investments and Large Industrial Equipment | H2020

LEVEL-UP will offer a scalable platform covering the overall lifecycle, ranging from the digital twins’ setup, modernisation actions to diagnose and predict the operation of physical assets, to the refurbishment and remanufacturing activities towards the end of life. In-situ repair technologies and the redesign for new upgraded components will be facilitated through virtual simulations for increased performance and lifetime.

Level-Up Project in order to achieve its purpose will make use of 10 special protocols for modernising, diagnosing, inspecting, repairing, disassembling, upgrading, refurbishing, remanufacturing, recycling and reassembly & testing. To enable companies to understand the details of each protocol, a Protocols Specification Document was created which provides guidelines for the ten protocols. Each protocol guideline provides a definition and detailed description of the protocol, including purposes, condition, as well as a list of detailed actions and steps. This document also includes a flowchart to visualize the process and interaction of different actions and steps in the hope to accelerate industrial companies to understand and adopt the LEVEL-UP protocols.

For more information about the 10 protocols read the PSD.

Pilot lines

Automotive Pilot LineIn October 2020 representatives from AIMEN Centro Tecnológico, travelled to ESTAMPACIONES MAYO facilities to install the distributed fiber optic sensors (FOS) in Fagor Arrasate transfer press. |

Woodworking Pilot LineLevel-Up Project partner Marlegno has begun the digitalization of its production process with the installation of the new OIKOS working center cutting station developed by project partner Scm Group.

|

Level-Up at a glance

To provide a brief presentation of the Level-Up project several communication materials were created.

For an overall idea of the project check out the Level-Up General Presentation.

For a quick glimpse over the project's main elements download the Digital Brochure.

Events

12 Month Meeting

During the 21st and 22nd of October the scheduled Level-Up EU Project 12M meeting was held successfully although.. digitally!Despite the covid19 restrictions, the consortium could get a first look of the seven pilot lines through virtual tours, analyze the technical progress so far and plan the next steps for the project.

Partners

Metal Machining Pilot Line

Metal Machining Pilot Line